In 2005 Tecnatom developed the airport electrical installations simulator (SILA) for AENA, a solution that is being widely used and that has achieved a high level of acceptance among its users. However, installations are modernised, technology evolves, the needs of the users change and our simulation capabilities never cease to grow. For this reason, in 2018 AENA decided to undertake an updating and modernisation programme in order for SILA to be able to continue providing as many benefits in the future as it does today. Tecnatom was selected by way of a public call for bids to carry out this update, guaranteeing compliance with AENA’s expectations as regards both technical capabilities and alignment with the latter’s culture and in-house policies.

What is the SILA?

At one time AENA identified the need for a training simulator capable of responding to certain problems associated with distributed electrical installations, the need to train operators on critical and infrequent manoeuvres and the difficulties involved in acting in the real world environment.

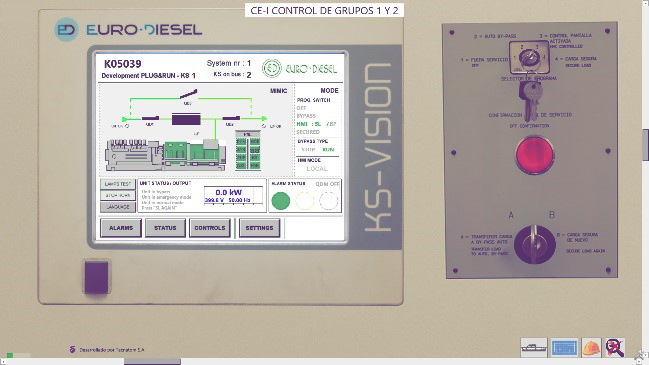

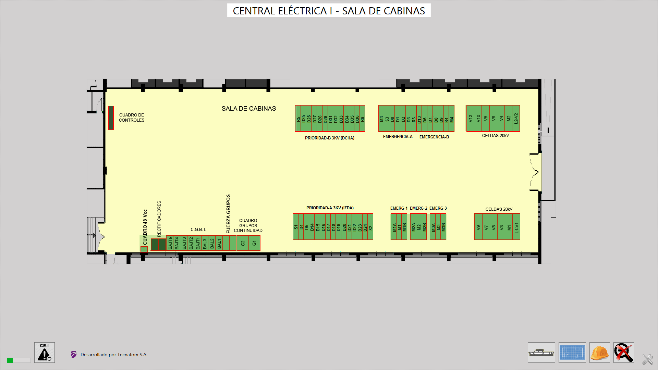

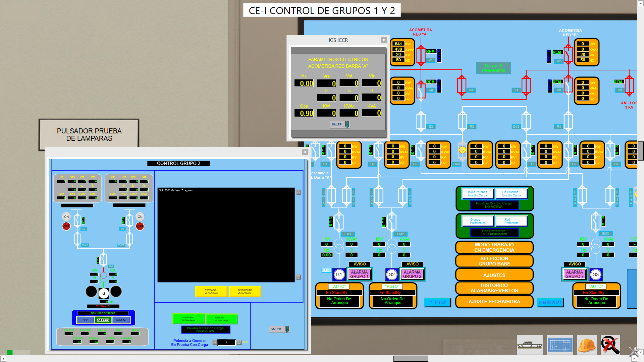

As a result, the SILA (Simulador de InstaLaciones Aeroportuarias) simulator project came about, a pioneer in its field. The main objective of this project is to improve the knowledge and operating skills of the operators of electrical installations at airports, although it is also designed for use in simulation assisted engineering activities such as the validation of operating procedures, pre-operational testing, design modification validation, etc. The simulator optimises the safety, availability and cost of an installation, since it allows for the reduction of training costs and the minimisation of operating errors and the time taken to recover in the event of a real electrical incident, with the impact on economics and public opinion that this would entail.

Why was it necessary to update the SILA?

There were three basic reasons: the condition of the hardware platform, the updating of the simulation model software and extension of the scope of the equipment and installations.

The hardware platform (based on Windows XP) and the simulation software tool (ProTrax models) are more than 10 years old and their respective manufacturers do not provide any technical support with respect to possible faults or problems in new developments. Consequently, there was a need to “rejuvenate” the hardware platform by replacing equipment and operating systems.

As regards the software, a graphic interface and model update was performed, this including a migration to in-house Tecnatom tools that removed dependence on third par ties.

As regards the widening of the scope, special mention might be made of the simulation of low voltage and climate-control facilities supplying CNS/ATM (Communication, Navigation and Surveillance/ Air Traffic Management) systems at two different sites. Also incorporated was the simulation of a climate control Scada (supervisory control and data acquisition) installation of a control tower.

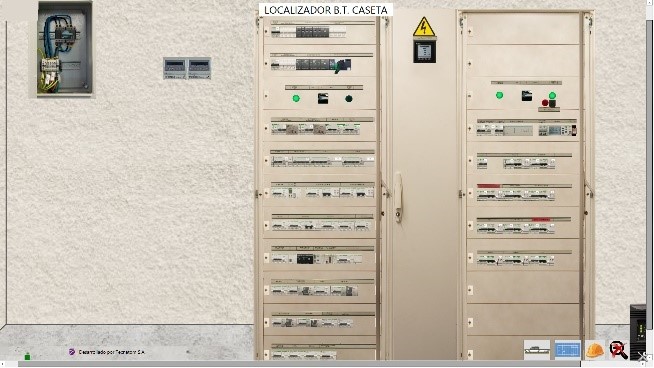

And with a view to training technicians in relation to the understanding and handling of the largest number of different items of equipment, new switchgear corresponding to reformed or recently built airport facilities was included, with new high voltage cabinets, multifunctional protective relays, rectifiers-chargers and low voltage breakers.

New technological capabilities

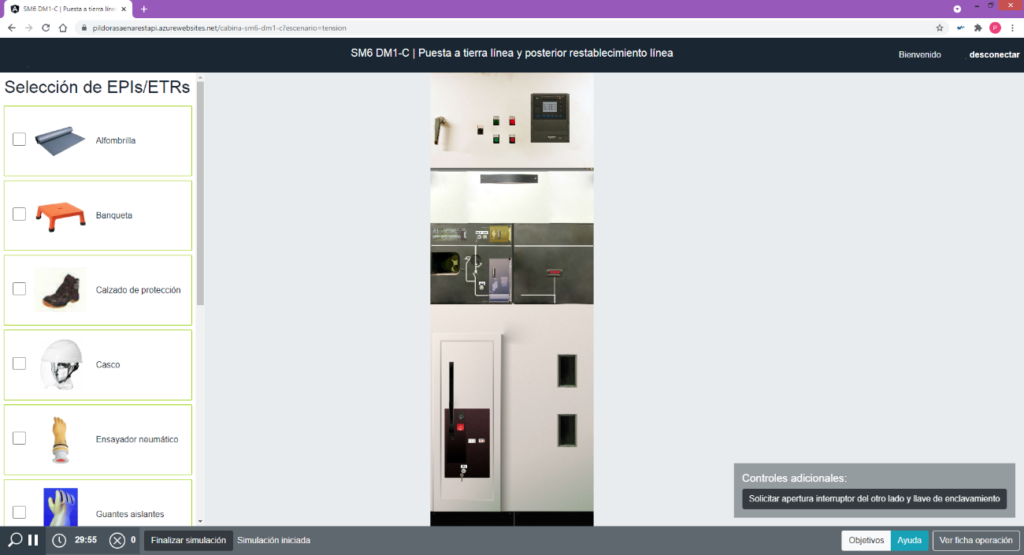

A set of 10 training pills has been developed as a support and complement to the simulator, these simulate 10 models of high/medium voltage cabinets.

Training pills are a new learning solution that has been developed based on the simulator and designed to allow the trainees to familiarise themselves with the interface of the cabinets and their logical and mechanical performance (key interlocks, levers, sound effects and the operation of lights) prior to training on the simulator. This allows greater advantage to be taken of the classroom courses and improves their duration.

As regards the training pills, practicality and brevity are essential. They are conceived for the in-depth study of specific issues and the acquisition of knowledge of these issues in a short space of time. The fact that these materials are accessible remotely and that the trainee may use them autonomously solves many of the potential availability limitations implied by a physical presence on the simulator.

Degree of customer satisfaction

On the simulator it is possible to create situations that would be impossible to reproduce on an actual installation, such as short-circuits or multiple faults. As a result, it is easy to reproduce and time certain manoeuvres and, therefore, improvements over time may be quantified. Thanks to use of the simulator, AENA has observed reductions in operator errors and performance times in training of up to 75%.

The operators gain in confidence and motivation in addressing unforeseen situations having a major impact on the installation and its activity.

The updating of the simulator and the extension of its scope have made it possible to considerably increase scenarios and manoeuvres, allowing for an even more complete and accurate training and providing a greater understanding of the new facilities and equipment.

Author: Ramón Izquierdo.