Integrated control centers – optimizing asset operation efficiency

What are Integrated control centers? The solution traditionally used to operate geographically dispersed power plants is to have an independent control center located at the

Development, installation and maintenance of the most competitive facilities in the sector

Inicio | Industrial Archives | Testing – Industrial

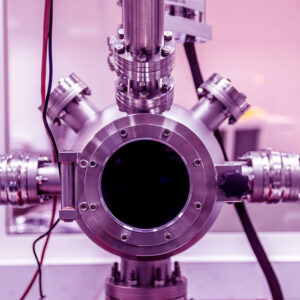

Safety in nuclear plants is an essential part of their commissioning. Tecnatom offers integrated solutions with the aim of verifying the operation capacity of the systems, equipment and components in nuclear plants. The Test Services offered by Tecnatom allow plants to meet the codes and standards required by the strict nuclear regulations, as well as providing a status diagnosis of its components to prevent faults, adjusting its maintenance plans to the real condition of the equipment and assessing its remaining lifespan.

The services provided by Tecnatom cover a wide spectrum including:

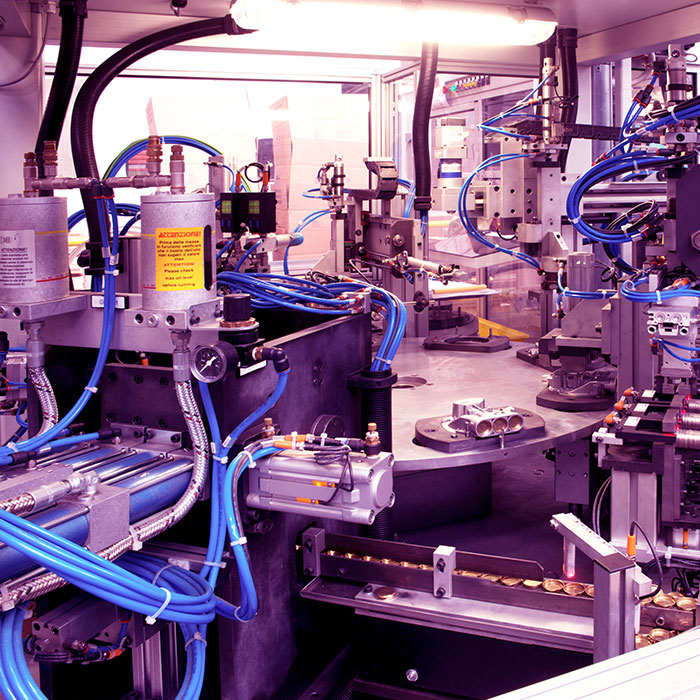

Test services are made through the installation of specific sensors on equipment and components with the aim of measuring the characteristic parameters of their behaviour in different conditions. Subsequently, a detailed analysis of these parameters provides us with a precise diagnostic of the tested equipment or component’s condition. To perform these tests, Tecnatom relies on the most advanced equipment used in the nuclear sector, which surpasses the requirements established in the applicable international regulations. Tecnatom also has a team of experienced, qualified professionals certified in various test methods and techniques a who prioritise our clients’ needs as well as the quality of their work and the safety of individuals and the facilities.

The industry is currently immersed in the revolutionary Industry 4.0 which will drastically change the paradigm in many of our fields of activity. Much of the system, equipment and component testing is susceptible to constant monitoring, which has a wealth of advantages including the ability to see an equipment’s status during plant operation, being able to carry out programmed tests immediately. The online monitoring of equipment significantly reduces the workload in test activities, optimising investments in maintenance and improving the performance and efficiency of the plan.

The integration of test services and maintenance constitutes as an added value having a direct implication on the efficiency of installations. Due to their similarities the integration of testing and maintenance on equipment has clear advantages, both from a work quality perspective as well as a resource and cost optimisation perspective. Tecnatom offers these types of solutions to its clients, with the aim of improving plant performance, increasing safety, efficiency and reliability.

What are Integrated control centers? The solution traditionally used to operate geographically dispersed power plants is to have an independent control center located at the

Within the framework of the transformation of work processes in the operation and maintenance of energy assets, Dynamic Instructions solutions stand out as a key

El proyecto ITER es uno de los proyectos de inversión más grandes del mundo, en el que colaboran más de 35 países con el objetivo de demostrar la viabilidad de la fusión nuclear como fuente de energía inagotable. Para ello se está construyendo uno de los dispositivos de fusión por confinamiento magnético más grandes del mundo, en el que se probarán tecnologías, materiales y regímenes físicos integrados necesarios para la producción de electricidad basada en la fusión.

Tecnatom forma parte del proyecto aportando la creación de la plataforma de simulación de lo que será el simulador de la sala de control de ITER, la integración de modelos existentes desarrollados por distintos suministradores, la integración del sistema de control CODAC, el desarrollo de modelos adicionales, así como el mantenimiento y la formación en la plataforma.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!