Fire protection is vital at any industrial facility and is a key activity at nuclear power plants. For this reason, Tecnatom has participated in a project aimed at validating the optimum status of the response to fires from the control room, from the point of view of human factors. The origin of this project is to be found in the publication of US NFPA (National Fire Protection Association) standard 805, “Performance-Based Standard for Fire Protection for Light Water Reactor Electric Generating Plants”. Subsequently, following the adoption of the aforementioned standard in the United States, the Nuclear Safety Council (Consejo de Seguridad Nuclear – CSN) transmitted the requirement to the Spanish nuclear power plants.

In the specific case of a nuclear power plant belonging to the Spanish fleet, the project included the preparation of scenarios on the full-scope simulator and their execution by actual plant shifts, under the supervision of experts in human factors. The performance of a project of this type implies interaction between people of widely varying profiles, such as specialists in operation, simulation and Human Factors Engineering (HFE).

The development of the project comprised the following stages:

Scenario design

Six scenarios were designed, covering fires in different plant locations and areas. The scenarios were analysed by a team combining expertise in operation and human factors, in order to take into account the following criteria:

- The challenges faced by the operating shift from the point of view of human factors.

- The failure modes leading to the most unfavourable plant operating conditions, thus working under the most conservative hypothesis, in accordance with the nuclear sector’s Safety Culture.

Test platform preparation

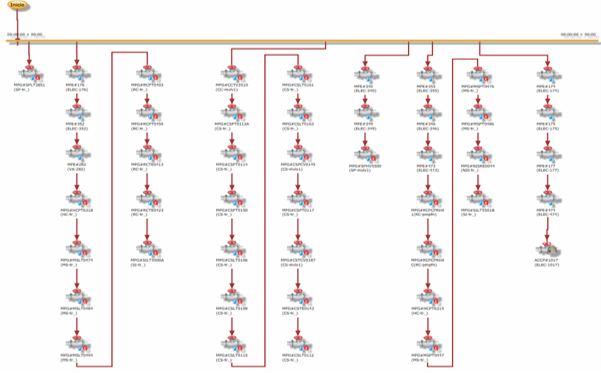

The full-scope simulator and the “Team Tutor”, a complex scenario creation tool, served as a platform for the development and fine tuning of scenarios. The use of the simulator, along with the participation of plant operators with no previous knowledge of the scenarios to be validated, created a test environment that was as true as possible to a real event.

The training scenarios executed on the simulator do not usually include massive component failures. Fire scenarios, however, include simultaneous failures or sequential failures occurring in a very short space of time and affecting various items of equipment at the scene of the fire. The sequence of equipment failures over time was also programmed using “Team Tutor”, this allowing a complete simulator session to be programmed without acting on the instructor’s console.

Scenario execution

All the scenarios were executed with two operating shifts in various sessions. The scenarios were supervised for validation by experts in Human Factors Engineering and operation as participants in the project, along with the CSN as an ‘independent validator’. The entire project team had in-depth knowledge of both the sequence of events and the expected operator response.

Results

On the one hand, the HFE team recorded the data gathered during execution of the scenarios, including information on the actions performed, by whom and on what items of equipment, along with the time taken to complete critical actions, and, on the other, additional factors were considered, such as operator situational awareness, workload and teamwork.

Also collected was all the information available on the simulator console in relation to the actions carried out, the corresponding times and the trends of different parameters. This information complemented the analysis performed during the observations.

The operators also carried out a subjective assessment of the execution of the scenarios by means of questionnaires specifically developed for the purpose.

The overall results obtained allowed the human factors engineering team to validate the scenarios executed, following their analysis.

Conclusions

The most important conclusions of the validation were that the plant procedures are suitable, with minor modifications, to address any fire scenario. It was also observed that the highest workload occurs at the beginning of the scenarios, when the emergency is declared, and that new types of scenarios are faced, different from traditional training sessions, with a much greater number of simultaneous failures.

These conclusions led to the decision to incorporate these scenarios into the training programs and to value the importance of having access to specific operating aids at certain moments.

The importance of this type of scenario validation projects based on human factors criteria is explained by the magnitude of the needs identified. In this case, the incorporation of new scenarios in operator training justifies the investments made in this and other similar projects, from the point of view of safety and operation.

Author: Borja Hervás