In a previous article it was explained that ultrasonics (UT) are habitually used in industry to ensure quality by detecting changes in the properties of both recently manufactured and in-service components.

In ultrasonic inspection, high frequency sound waves are transmitted through the material and are picked up after interacting with the different elements of the component, thereby allowing any heterogeneities to be detected.

The most important advantages of this NDT (Non-Destructive Testing) method are quite clear:

- High power of penetration that provides information on the volume of the part.

- Accurate reporting of the position and size of possible anomalies or heterogeneities.

What are the advantages of lasers in NDT?

The appearance of advanced ‘one shot’ manufacturing in the field of composites and of additive manufacturing in metal field have allowed for the evolution of component geometries in both the aeronautical and industrial sectors.

Conventional transducers do not adapt well to double curvatures and are not resistant to high temperatures, their use for the inspection of small diameter radii is not feasible and the edges of parts require specific inspections. For all these reasons, it makes sense to perform inspections without any contact, and it is in such cases that Laser Ultrasonics (LUS, Laser UltraSonics) become especially relevant.

How are lasers used to generate ultrasounds?

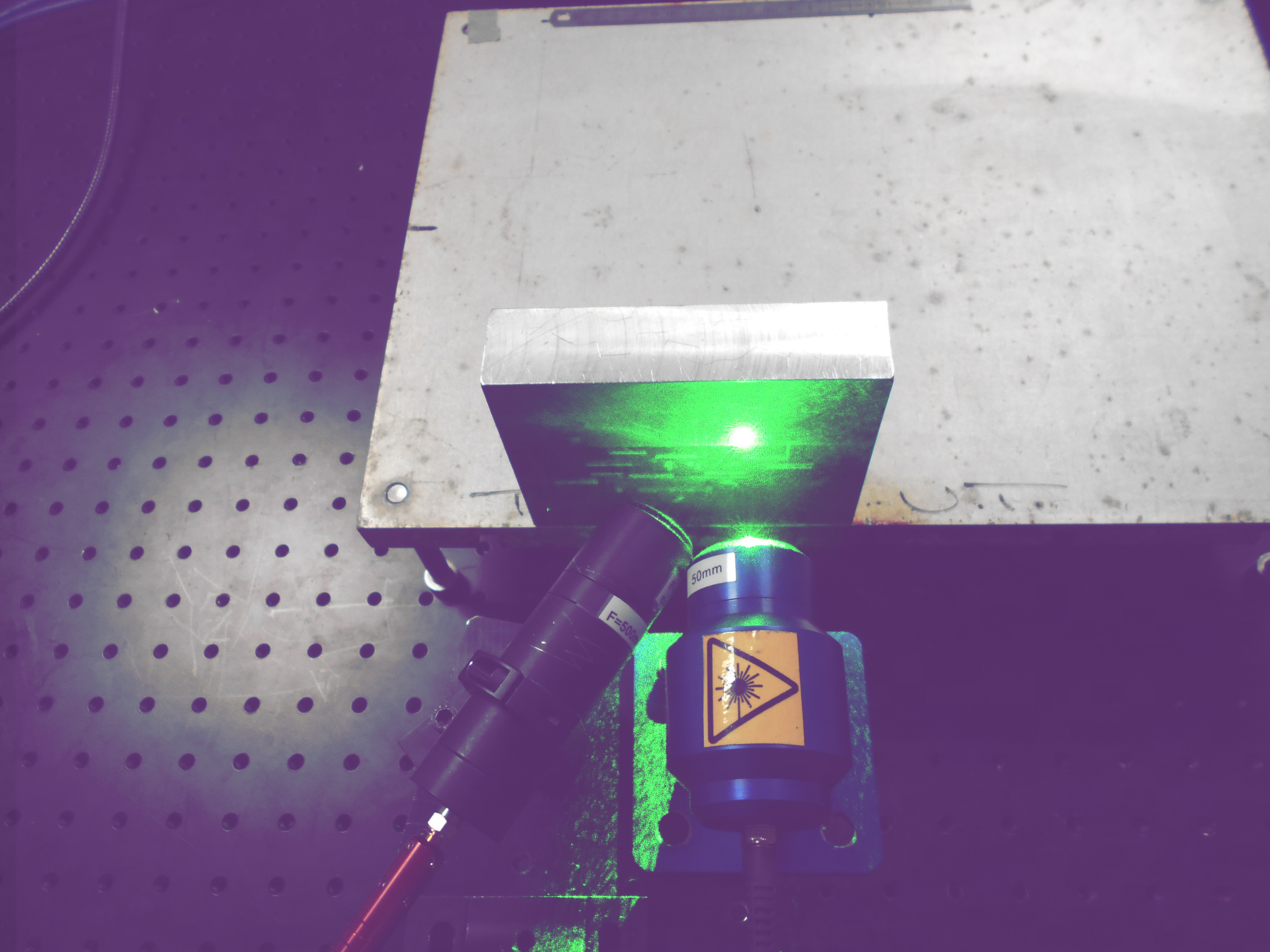

The LUS method is a part of the ‘UT beyond the coupling medium’ approach. In LUS, the generation of ultrasounds results from phenomena occurring on the surface of the component following the impact of laser pulses. The detection of the resulting ultrasonic wave, on the other hand, is accomplished by means of a system consisting fundamentally of a specific detection laser and an interferometer.

The importance of the fundamentals of the LUS technique

Tecnatom uses the fundamentals of the LUS technique in equipment to which are incorporated automation tools and solutions through our hardware and software technology.

In this way it is provided technical know-how regarding the technology and integrate it efficiently into the overall inspection process. In addition, work is on-going in the development of laser ultrasonic (LUS) systems for the inspection of the metallic materials of specific components.

An example of this technology may be found in the case of the tecnaLUS equipment, developed jointly by Tecnatom and Airbus Defence & Space. This equipment has been validated at the installations of the aeronautical multinational, specifically at the Airbus CBC facilities, and is used for quality control during the aircraft parts manufacturing phase.

The state of the art in the industry today

Despite the promising characteristics of Laser UT, the industry has been reluctant to embrace the technology. Composite manufacturers that are looking for ways to optimize their NDT processes, generally opt for alternative solutions such as Taurus or WiiPA. The reasons for this can be found in some of the drawbacks that automated Laser UT systems present:

- Elevated cost of high-powered laser technology

- Limited to monolithic materials (no sandwiched material structures)

- Single supplier for critical components

- Specific expertise required to operate systems

- High maintenance and support costs

Although Laser UT may have its place in the NDT field for very specific applications or in material research, the use of this technology in industrial production processes (in the aeronautical industry) has not been able to meet the ambitious expectations. Tecnatom has ample experience with Laser UT, more conventional UT techniques and any NDT method in general. As a service and technology provider, Tecnatom can give knowledge-based and balanced advice or solutions for any NDT application or project.

Author: Covadonga Garcia