One of the main revolutions in energy transition, apart from clearly backing renewable energies in order to decarbonise energy consumption and generation, is recognition of the fact that the end consumer must play an active role in this transition and not act as a mere spectator.

In recent years this has led to an increasing proliferation of auto-consumption facilities, be they for business, institutional or private consumers, these allowing the consumer to generate his own energy and reduce his reliance on the electricity grid.

These facilities may operate individually or in association through the figure of the energy community, in which different members or partners come together to generate and consume their own power, sharing the economic, social and environmental benefits.

In the wake of the latest changes in electricity billing, which came into force on June 1st last, the implementation of an individual or collective auto-consumption facility becomes more meaningful than ever, the aim being to reduce grid consumption during peak periods.

Further changes are expected in late 2021 and early 2022, following the transposition of the corresponding European directives, which will regulate the role of the independent aggregator (generation, demand or storage) and Virtual Power Plants (VPPs). This will imply a complete change of paradigm since it will be possible to sell the surplus power from facilities coupled to the grid, carry out energy trading activities, etc., and all this without limits on the distance between generator and consumer.

Given this new scenario, current energy communities and future distributed resources managers (independent aggregators and VPPs) must begin to take actions and gain insight into the different solutions available on the market that might help them to suitably plan and manage their distributed resources, gaining the maximum economic advantage and minimising the initial investment.

To accomplish this, they must have available solutions allowing them to perform the following:

1. Optimum aggregation configuration

The suitable dimensioning of generation and storage to cover consumption will be a determining factor to minimise initial and operational investments, maximising economic returns.

This will require the availability of a tool for the calculation of optimum dimensioning and its testing in a virtual installation in order to adjust it before development of the actual facility.

2. Validation and optimisation of the Control System

The control system of a distributed energy resource (DER) aggregation will manage the energy flows of the latter, deciding when would be the best moment to consume what has been generated, when and how to store it, when to consume from the grid, when to sell surplus production, etc.

Validating the satisfactory operation of the system, and even more so optimising this operation, is crucial not only for the suitable management of the aggregated installations but also to maximise their economic returns and respond to incidents affecting them.

3. Prediction of DER aggregation economic returns

Predicting the generation estimated for the coming hours, days, months or years is key to being able to optimise generation-storage-consumption energy flows. This would make it possible to obtain surplus energy that could be sold on the different electricity markets, obtaining an economic return that could be shared among the partners.

Awareness of these economic returns beforehand allows the profits that each partner might obtain collectively and individually to be compared during the phase of attracting customers.

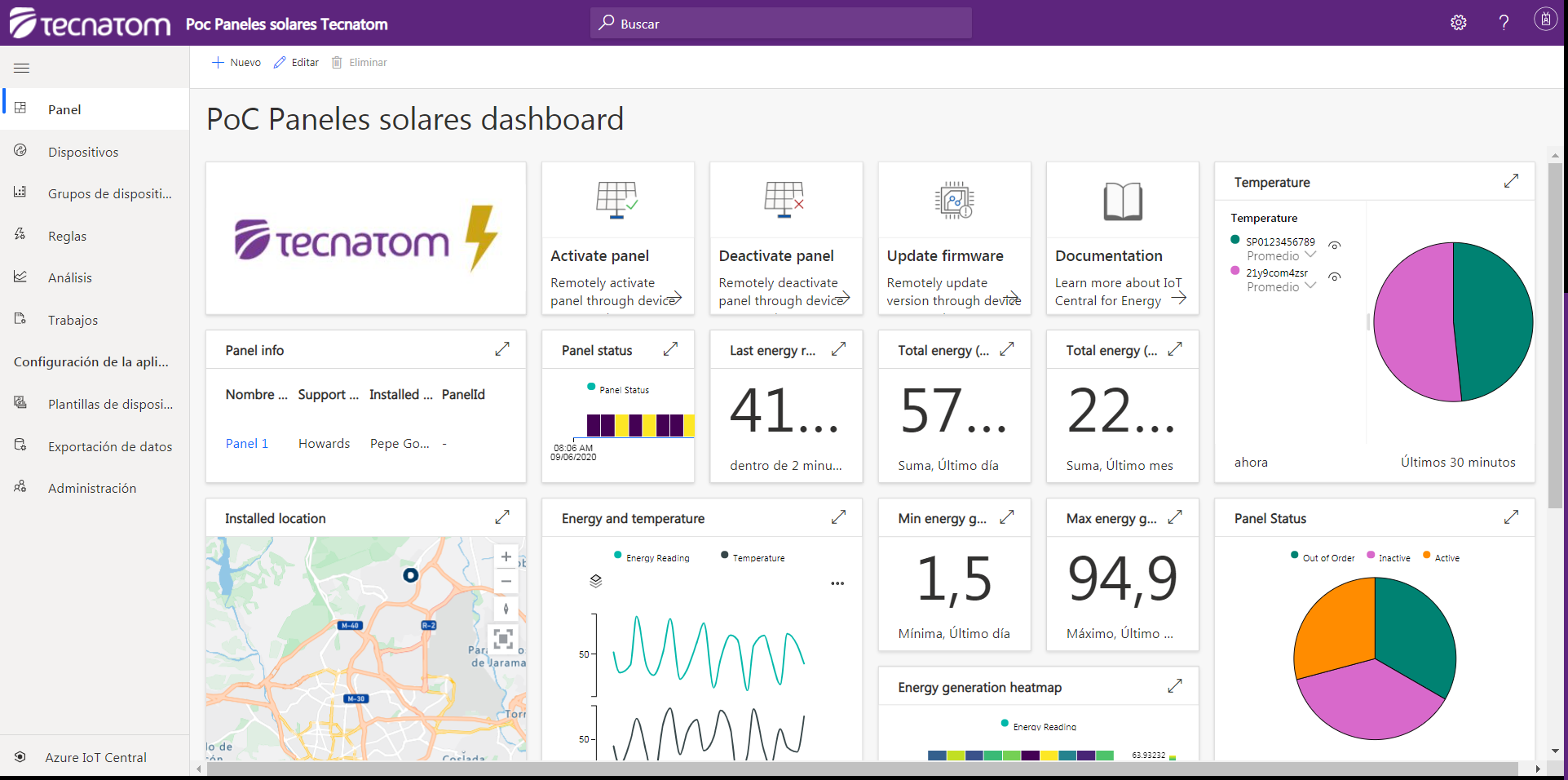

4. Technical and economic monitoring of aggregate installations

The monitoring of aggregate installations, in energy-related, economic and CO2 reduction terms, makes it possible to identify improvements in the performance of the installations and to anticipate possible faults, in order to be able to take suitable operation and maintenance decisions.

5. Solution tested in pilot projects or concept trials

In addition to fulfilling these functionalities, it would be appropriate for the selected solution to have been tested to gain insight into the benefits that might be obtained.

Tecnatom has developed the Aggrefy solution, which fulfils all the aforementioned technical functionalities. In addition, as it is a Digital Twin, it not only allows aggregate installations to be monitored in real time but also makes it possible to simulate different strategies in order to anticipate the results of their implementation prior to decision-making. The above does not affect the actual installations since it is carried out in a virtual facility replicating the real one as regards both appearance and behaviour.

According to a pilot project performed by aggregating several photovoltaic generation (FV) installations, with batteries and electrical vehicle charging posts, the benefits that might be obtained thanks to Aggrefy are as follows:

- 5-10% increase in the energy efficiency of aggregate installations.

- 3-7% reduction in greenhouse gas (GG) emissions.

- 15-20% maximisation of economic returns due to optimum management of FV facilities with batteries.

For further information on this product, please contact us on Tec4GRIDS. We will give you a DEMO and help you with the entire process, from planning to the overall management of your DERs.

Author: Ana Izquierdo