Automated analysis of Baffle Bolts

Tecnatom will present in the next 13th European Congress of NDT the Project about theAutomated Analysis of Baffle Bolts. The congress will take place from

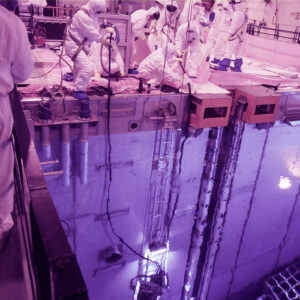

Assuring the integrity of all the components in a nuclear plant

Inicio | Nuclear Archives | Inspection Services – Nuclear

Our objective is to always help our clients meet their high safety standards, proposing efficient inspection solutions based on global services which reduce costs and increase process efficiency.

Tecnatom is able to develop NDT inspections for all the critical components of a nuclear plant, from the reactor vessel to the steam generators, including internal parts, nozzles, pipes, heat exchangers, condensers, nuclear fuel etc.

We design NDT solutions in continuous collaboration with our clients, identifying the plan best suited to the availability of the plant.

Once the inspection has been assessed, inspection solutions are then identified which contain both the applicable procedures (in accordance with the required regulations), and the definition of the inspection system (mechanical system and NDT equipment).

At Tecnatom we have our own tools that have allowed us to develop numerous inspection system technologies, both automatic and manual, meaning we can offer services that use all types of NDT methods: ultrasound (Air-Coupled UT , laser generated or Phased Array), eddy current, dye penetrant, magnetic particle, radiography (digital and conventional), thermography, etc.

In the inspections carried out by our NDT experts, we use our highly versatile inspection systems, which are able to adapt to the diverse geometrics and thickness of components.

Our systems can be modified as per the specific needs of our clients so as to comply with complex inspection requirements. To do this Tecnatom has a technology development department which allows us to successfully embrace new requirements in accordance with regulations. We can also adapt new inspection technology which can only be applied to certain components.

Our vast international NDT experience means we have enormous flexibility and agility when taking on any NDT inspection technique challenge.

At Tecnatom we are international leaders in the development of Non-Destructive Testing technology, from its specification and inspection technique development to its implementation into robotic and autonomous systems. This also includes the development and manufacture of ultrasonic and eddy current equipment Hardware and Software. This technological independence allows the robotic equipment we use in our inspections (designed and manufactured by our experts) to possess enormous versatility, thus facilitating the inspection process. It also increases efficiency and reduces time and costs for our clients.

This is all possible thanks to our sustained faith in R+D investment. We are conscious of the fact that a solid technological base is fundamental for our growth. In addition to our technological capacity we also have profound knowledge and experience in Non-Destructive Testing, making us expert global leaders as nuclear plant system and component specialists, regardless of the technology present or the differing international standards.

At Tecnatom we know that technology, knowledge and experience are the keys to optimising efficiency in NDT inspections, and contribute to the safe and optimum operation of nuclear plants.

Tecnatom will present in the next 13th European Congress of NDT the Project about theAutomated Analysis of Baffle Bolts. The congress will take place from

NEXA™ Will Leverage Companies’ Expertise in Technology, Training and Operations Atlanta, Ga. – April 18, 2023 – Westinghouse Electric Company, Tecnatom and Accelerant Solutions announced

El proyecto ITER es uno de los proyectos de inversión más grandes del mundo, en el que colaboran más de 35 países con el objetivo de demostrar la viabilidad de la fusión nuclear como fuente de energía inagotable. Para ello se está construyendo uno de los dispositivos de fusión por confinamiento magnético más grandes del mundo, en el que se probarán tecnologías, materiales y regímenes físicos integrados necesarios para la producción de electricidad basada en la fusión.

Tecnatom forma parte del proyecto aportando la creación de la plataforma de simulación de lo que será el simulador de la sala de control de ITER, la integración de modelos existentes desarrollados por distintos suministradores, la integración del sistema de control CODAC, el desarrollo de modelos adicionales, así como el mantenimiento y la formación en la plataforma.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!