As is described in our article “Ultrasonics. Beyond the coupling medium” , dry inspection makes it possible to address the evaluation of components under extreme working conditions, the inspection of complex geometry elements, the reduction of surface contamination on parts and the avoidance of the need to install water circuits in productive machines, also facilitating the inspection processes.

Together this translates into shorter working times and consequently a reduction of inspection and maintenance costs.

Mention may be made of the following dry ultrasonic non-destructive testing techniques:

EMAT (ElectroMagnetic Acoustic Transducer)

Air-coupled ultrasound (UT Air) and the use of Rollscan

What materials can we inspect?

The EMAT technique (link) is based on ultrasonic generation by means of electromagnetic phenomena. It may be used on electrically conducting materials; in other words, it may be said to work with practically all metals.

However, there are some that are more favourable for use with this technique than others, since it is more effective with ferromagnetic metals. On the market there are systems that operate from 50kHz to 5 MHz, for use both in inspection during manufacturing and in service.

The laser ultrasonics is based on the generation of ultrasounds through the impact of a laser pulse and allows for the inspection of composite material laminates (carbon fibre and glass fibre), as well as of metals.

We have wide experience of using this technique, especially on metals such as aluminium, carbon steel and stainless steel, this being more favourable the lighter the metal.

Another noteworthy application of this technique is the inspection of welds. The working frequencies range from 100 kHz and 10 MHz. Depending on the material to be inspected, references will be to pulse-echo, transmission or pitch and catch inspection.

Composite materials and reduced thickness metals may also be inspected using the Air-coupled ultrasound technique. Low frequency ultrasounds (between 50 and 700 kHz) are used with this technique and it is very useful for the inspection of high attenuation parts that cannot be dampened because of their characteristics or end use, for example honeycomb or foam in the aerospace sector. Generally speaking, the transmission technique is used, although the guided wave pitch-catch technique may be used for the inspection of welded metal joints.

Finally, rollscan (UT coupled wheel probes. Beyond the coupling medium, LINK) operate with a wide range of frequencies, depending on the needs of the application, even with low frequencies in the case of highly attenuating materials such as some of those used in the aerospace sector.

Rollscan may have conventional or phased-array probes installed in their interior, as a result of which there is a wide variety of sizes, frequencies and uses and they may be operated in both pulse-echo and transmission mode.

In what applications would it be convenient to use each technique?

The thing that all the aforementioned techniques have in common is that they are appropriate for industrial applications in which inspection speed and accuracy are fundamental. It is important to underline the fact that all of them may be automated in order to improve the efficiency of the processes, thereby increasing the production of the facilities. Our Taurus robot-operated system for the inspection of aerospace parts is a clear example of this.

The EMAT technology and the use of rollscan are adapted for inspection in the field and are very useful for the maintenance of components, although they may also be automated. They may be particularly interesting for inspections in areas presenting a risk of radiological contamination in the nuclear industry, since they minimise the possibility of interaction with external substances.

Laser ultrasonic and air-coupled ultrasound (UT Air) make greater sense in quality control during the component manufacturing stage or in automatic inspections, since the corresponding systems require great accuracy and stability for their use.

Depending on engineering requirements, each application requires a specific preliminary study and technical analysis ensuring the best results and, fundamentally, meeting the necessary expectations.

Is it possible to compare inspection results using different contactless ultrasonic techniques?

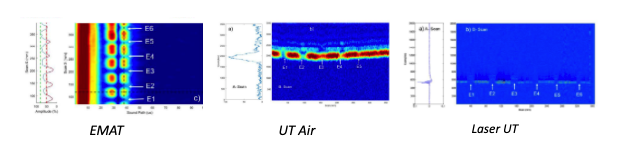

It depends on each individual application. For example, at Tecnatom a study was performed for the inspection of welded plates of different materials and thicknesses in order to assess the applicability of different techniques under dry conditions (EMAT, UT Air and laser UT). A comparison of the results is shown below:

The results show that the known indications on the plates are detected with any of the techniques applied, albeit with different degrees of accuracy. The advantages and limitations of each application are shown by way of a summary:

Los resultados muestran que las indicaciones conocidas de las placas se detectan con cualquiera de las técnicas aplicadas, aunque con diferente precisión. A modo de resumen se muestran las ventajas y limitaciones de cada aplicación:

| Technologies | Limitations | Advantages |

| Emission-reception of guided SH waves generated using EMAT technology |

|

|

| Emission-reception of Lamb waves generated by air-coupled ultrasonics |

|

|

| Emission-reception of Lamb waves generated by laser ultrasonics |

|

Authors: Covadonga Garcia and Amador Sillero