PTC Manager

Track gas turbine main components life management, documenting all the actions carried out and storing all the information related to their costs. This solution contributes to manage the gas trubine components and optimize the maintenance costs.

Benefits

Integrated data

- Codified database for all components and functional locations.

- Historical data of all the start-ups and operation tracking.

Components like management

- Control of Equivalent Operating Hours (EOH), Start-ups, Remnant life, refurbishments .

- EOH projection to schedule replacements.

Optimized maintenance costs

- Maintenance costs tracking for gas turbine main components including reject costs

- Optimizing maintenance budgets from OEM.

OptiLife PTC-Manager features

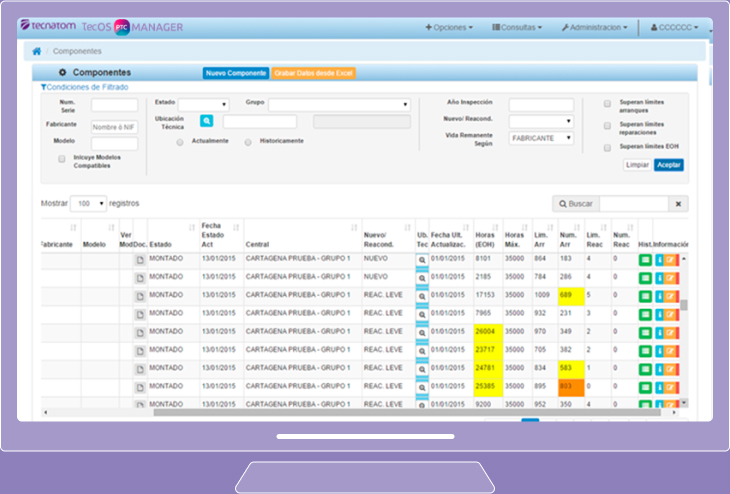

Gas turbines components management

- Components and functional locations codified.

- Management of massive changes in components status.

Tracking of components history

- According to the status (mounted, warehouse, stock) and Operation history (EOH, start-ups, refurbishments).

- Costs tracking.

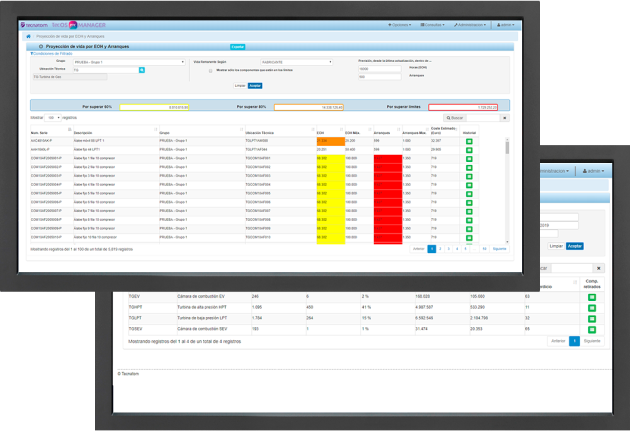

Proyected life calculation

- Remnant life calculation based on EOH and start-ups according to the vendor or standard independent methodologies.

- Schedule components replacement based on projected operating hours.

How does it work?

EXECUTION

OptiLife PTC Manager is used in plants with gas turbines such as combined cycles, open cycle plants, cogeneration, Oil&Gas or other industries.

USERS

OptiLife PTC Manager main users are the plants maintenance managers.

FAQs

Can I implement OptiLife PTC Manager in my currently operating plant?

Yes, if the operation information and components replacements records are available you can implement it.

What deployment supports OptiLife PTC Manager?

This web-based application can be deployed on-premise or on-cloud.

How can OptiLife PTC Manager help me during the LTSA negotiation?

It is an important tool to support our clients during LTSA negotiation.