Monitoring Center

Remote Monitoring Services for Energy Plants

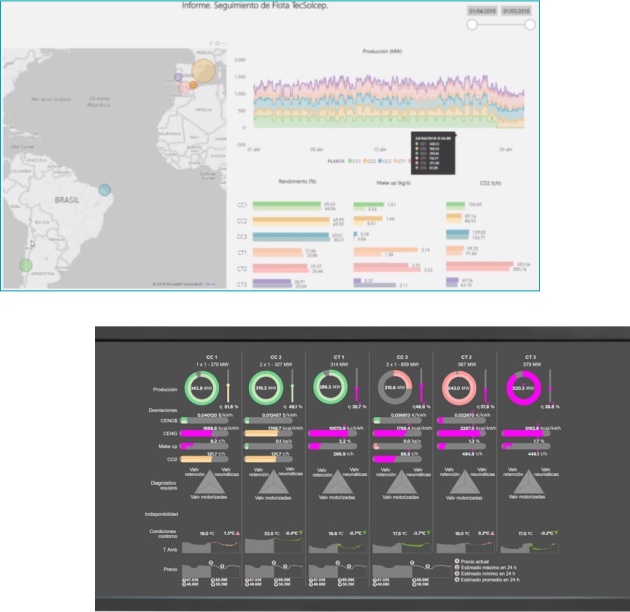

ON-LINE FLEET/PLANT STATUS

PLANT PERFORMANCE & ASSET CONDITION

ALERTS ON POOR PERFORMANCE, FAILURE RISK AND DIAGNOSIS

REPORTS

TECHNICAL SUPPORT

Data flow: from field signal to monitoring services

DATA INGESTION

DATA SECURE

DATA INTEGRATION

PROCESSING AND ANALYSIS

VISUALIZATION

DATA INGESTION

DATA INGESTION

DATA INTEGRATION

PROCESSING AND ANALYSIS

How do we carry out nuclear component engineering?

Experts focused on costumers

- Experts in operations, performance, maintenance, processes, and engineering.

- Using the cutting-edge OptiLife tools.

Advanced Interfaces

- Application of human factor engineering geared towards minimizing human error, reducing cognitive load, and improving ergonomics.

- Smart icons developed by Tecnatom to present, in a visual and comprehensive way, the most representative parameters.

Data Analysis

- Data analysis applied for early detection, diagnosis, and prediction of anomalies.

- Our team of data scientists tackles the analysis of complex problems, combining process knowledge with advanced algorithms.

Adaptable and Flexible

- Functional scope that is flexible and adaptable to our clients’ needs and requirements.

Tecnatom Monitoring Center features

Reduction of operation and maintenance costs.

- Optimization of O&M costs thanks to the reduction of fuel consumption, the reduction of equipment failures, and the implementation of predictive maintenance.

- Economic approach by identifying and monetizing the impact of losses.

Early detection of anomalies.

- Data analysis aimed at reducing equipment failures.

- High-performance interfaces that facilitate early identification of events.

- Real-time data access.

Supporting decision making.

- Analysis, diagnosis, and recommendations based on criteria from expert analysts from different fields.

- Identification of best practices and lessons learned.

What can you do?

Plant operations and maintenance strategies can be optimized thanks to real-time knowledge on equipment efficiency and condition. Scope:

- Monitor performance with OptiLife SOLCEP

- Foresee degradation and emerging equipment problems with OptiLife FORESEE.

- Monitor the state of components like valves, transformers, motors, and structures.

Our expert analysts rely on these tools and on their process knowledge to report events, to make recommendations, and to offer personalized advice.

How does it work?

Tecnatom Monitoring Center aims to support energy plants to optimize operation and maintenance. The data and the OptiLife solutions provide support for our monitoring and diagnosis services.

Inside the CMT

The team

The CMT team uses different profiles from analysts and experts who work collaboratively with plants. The center’s staff is supported by their knowledge on the technologies, processes, and tools to be able to make the most of the available data. Our relationship with our clients is based on transparency. We design communication processes based upon our clients’ specific needs. In addition, CMT includes simulators that Tecnatom has developed and that allow to test different scenarios and give recommendations to our clients.

Interfaces

The information processed in the CMT is shown through smart interfaces that, thanks to pattern recognition and the integration of information, allow to identify anomalies at a glance. The use of smart icons, developed by Tecnatom, help to present information in a comprehensive, intuitive way, reducing the cognitive load on the user and favoring situational awareness. Tecnatom’s experience in human factor engineering has given rise to a design aimed at facilitating the work of analysts.

Services provided by the Monitoring Center

Periodic reports

On-Demand Services

Communications and Accesibility

Access to operating experience and best practices

Periodic reports

- Operational reports.

- Reports focused on accounting.

- Reports with an executive profile.

On-demand services On-demand analysis and assessment to face unfamiliar situations. Diagnosis of in

- Diagnosis of inefficient situations.

- Analysis of instrumentation.

- Assessment of when it is appropriate to undertake certain maintenance.

Direct communication and accessibility to solutions and data.

FAQs

What are the on-demand services?

Instrumentation analysis, process optimization recommendations, inefficient situation diagnosis, deviation impact analysis to support decision making.

Does any software or hardware need to be installed in the plant?

Performance and component monitoring both require data sources and communications solutions. Storage takes place in a data management system. The best solution for deployment will be sought to meet the client’s needs

How does the CMT get its data?

The architecture for acquisition, transport, and storage is flexible and adaptable to the client’s needs. CMT software has a wide variety of connectors to transmit and storage plant data in order to be able to take advantage of the data once it has been processed.

What dedication is needed by the plant team?

The communication process with plant staff is tailored to the needs of each client. Staff should be available for weekly and monthly follow-up, as well as being able to tend to alerts set off by monitoring system incidents.